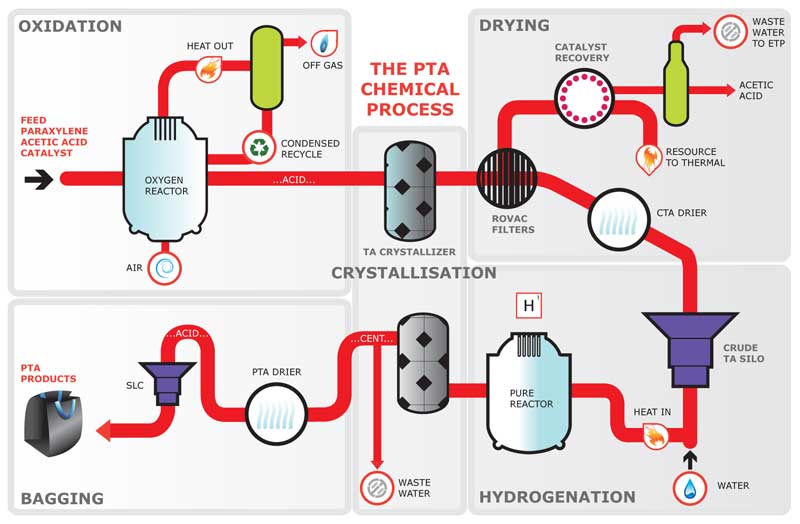

In the second stage known as purification, the crude TA is re-dissolved in hot water, co-products are removed by hydrogenation and pure terephthalic acid is again crystallised out and dried. This ensures that the 99.98% purity required for the manufacture of polyester products is achieved.

Various ancillary stages are required to ensure waste recovery and raw material efficiency and the process requires nitrogen, hydrogen, natural, large quantities of fresh water and significant electrical power.

Methyl Acetate is produced as a by-product, which is recycled to Oxidation reactor to minimize acetic acid losses.

Liquid effluent from the process is biologically treated using a deep shaft technology, so that the final water being discharged fully conforms to the National Environmental Quality Standards (NEQS).

| Appearance | White, free flowing crystalline powder, free from visible contamination |

| Acid Number(mg KOH/g) | 675 + 2 |

| 4-Carboxybenzaldehyde (ppm w/w) | Max 20 |

| p-toluic acid (ppm w/w) | Max 170 |

| Benzoic acid (ppm w/w) | Max 30 |

| Al,Ca,Co,Cr,Fe,K,Mg,Mn,Na,Ni,Ti,(ppm w/w) | None greater than 1 and in total max 4 |

| Water (% pct w/w) | Max 0.15 |

| Ash (ppm w/w) | Max 6 |

| Millipore | Min 0.90 |

| Appearance compared with standard | Acceptable |

| b* colour | 0.4 – 1.2 |

| Typical Physical Properties | |

| Molecular weight | 166.13 |

| Melting Point in sealed tube (°C) | 425 (sublimation occurs above 300°C at atmospheric pressure). |

| Solubility | 1 part in 67,000 parts water at 10 °C. Partially soluble in dimethyl formamide and pyridine. |

| Typical median particle size range (micron) | 130 ± 25 |

| Typical bulk density g/ml (DIN 53194) | 1.12 |

| Typical angle of repose (degrees) (poured) | Poured 40 |

Last Updated on November 23, 2014